European leader in mattress recycling and circular materials.

The solution is here.

What we do

We operate a fully circular mattress system across Europe, from dismantling to high-value material recovery and recycled raw materials.

With sites in the Netherlands, the UK and France, we form a trusted cross-border ecosystem that supports retailers, municipalities and manufacturers in meeting the next generation of circularity standards.

How?

We make the system circular by collecting, dismantling, rejuvenating and processing post-consumer mattresses. Through our unique recycling method, we recover valuable materials like:

- RePoliol – high-quality recycled polyol used in new foam products

- Rebond foam – used for sports fields, playgrounds, and underlays

- Steel and textiles – reused in manufacturing and construction

In traditional systems, used mattresses are collected and incinerated. In our system, they’re refurbished, dismantled, transformed, and returned to the market as certified circular materials.

Facts & Figures

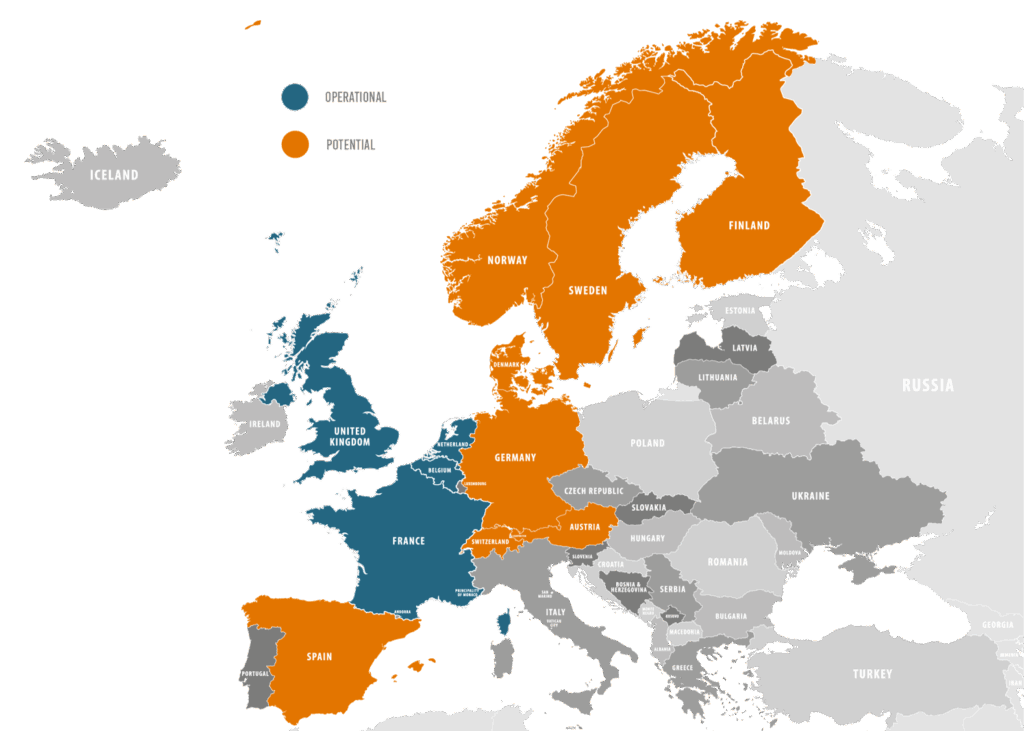

Expanding Europe’s circular infrastructure

With operational sites in the Netherlands, the UK and France, we are scaling up circular solutions across Europe. New locations are in preparation to meet rising demand from suppliers, manufacturers, and investors.

We aim to build local ecosystems, reducing transport emissions and returning value to the communities that supply the waste.

Our group structure

Unlike most recyclers, we are vertically integrated: we also manufacture new materials and products from the recovered foam, like Rebond and RePoliol. This creates full traceability and control over the circular chain.

Why it matters

The EU is tightening regulations on waste management and recycled content. By working with RetourMatras Group, stakeholders ensure compliance with future legislation, while contributing to measurable climate impact.

In traditional waste chains, the end destination is often unclear. We provide full visibility on where materials go ,and how they add value in new products.

We actively contribute to European policy and innovation through working groups and associations like Europur and FEAD.

The RetourMatras Method

Our fully automated dismantling line increases both speed and safety, while reducing costs.

- High-speed dismantling for all mattress types

- Clean separation of foams, metals and textiles

- In-line quality control

- Scalable, modular infrastructure

- Developed in-house with specialist partners

A measurable climate impact

Each year, our Dutch recycling operations prevent up to 152,000 tonnes of CO₂ emissions compared to incineration.

That’s the same as one million passenger flights from Amsterdam to Paris.

As our group expands across Europe, this impact continues to grow.

And through refurbishment and chemical recycling, we reduce even more.

Trusted by industry leaders

Enabling circular compliance

For municipalities:

- Fully certified, low-transport collection system

- Compacting containers with automated pick-up triggers

- Insightful reporting and long-term contracts

For producers & retailers:

- Guaranteed traceability

- Scalable supply with ISO certification

- Reliable partnerships for many years

Contact us

Whether you’re a municipality, investor, or sustainability manager: we would love to get in touch.

Contact us to learn more about how RetourMatras Group can support your circular goals.

info@retourmatras.nl

+31 (0)321-800 000